What is Weight Distribution Hitch (WDH)?

Before digging deep down into every detail of a WDH, we must know what a WDH is. To put it simply, WDH or weight distribution hitch is a system that helps create a level and stability for the travel trailer you are towing.

What Does a WDH Do?

Weight distribution hitch or an anti-sway hitch is designed to perform a variety of functions:

- Firstly, it distributes the tongue load to the truck and eliminates flexibility in the vertical plane.

- Secondly, it smooths out the ride considerably by providing comfortable travel with less bobbing and less sway.

- Thirdly, it prevents the travel trailer from bouncing whenever you hit a bump or uneven pavement.

- Lastly, it prevents the rear of the truck from sagging.

How Does a WDH Work?

The WDH works by altering the point at which the trailer’s load is transferred to the vehicle.

Usually, the tow ball weight of the travel trailer is carried at the tow ball, and the WDH corrects this by distributing the weight across the axles of the trailer and vehicle just like you lift a wheelbarrow.

When do You Need a Weight Distribution Hitch?

Having a weight-distribution hitch is a must if you are towing a travel trailer weighing more than 4000 pounds. There are several circumstances where you will need a WDH. Some of these circumstances are the following:

- When the tongue weight exceeds the manufacturers hitch rating for weight carrying ability

- When the rear of the tow vehicle sags so much that headlights don’t aim properly

- When the steering is out of control or light

- When you exceed the rear axle or tire loading ratings of the tow vehicle

- When the trailer feels like it has taken control of the tow vehicle whenever you hitch it up

Why is It Important to Use WDH?

WDH is an important component for your truck to pull a travel trailer. Following are some pointers that define why it is important to use a WDH.

- It rebalances the vehicle

- Makes braking stable

- Reduces the tongue weight

- Provides a great sway control

- It makes the weight even between each axel

- Weights the front axle so that the steering isn’t compromised

Things to Consider When Choosing:

Purchasing a perfect WDH for your travel trailer is always difficult as you have to consider numerous things. Following are some of the key things that should be considered while you choose a WDH:

- Determine the total weight of the trailer loaded and empty, and your tongue weight

- Check the vehicle’s owner manual to check for the appropriate size range of WDH for your vehicle

- The height of the trailer’s hitch and hitch ball should be almost the same

- The vertical adjustability of the ball mount relative to the hitch bar.

Best Weight Distribution Hitch for Travel Trailer

Position | Preview | Name | Price |

1. | Husky 30849 Round Bar Weight Distribution Hitch | ||

2. | Husky 32218 Center Line TS with Spring Bars | ||

3. | CURT 17022 Round Bar Weight Distribution Hitch | ||

4. | CURT 17062 Round Bar Weight Distribution Hitch | ||

5. | Fastway e2 2-Point Sway Control Round Bar Hitch | ||

6. | Equal-i-zer 4-point Sway Control Hitch | ||

7. | Blue Ox BXW1000 SWAYPRO Weight Distributing Hitch | ||

8. | Reese Integrated Sway Control Weight Distribution Kit | ||

9. | EAZ LIFT 48703 Trekker Weight Distributing Hitch | ||

10. | Reese Pro 49903 Round Bar Weight Distribution Kit |

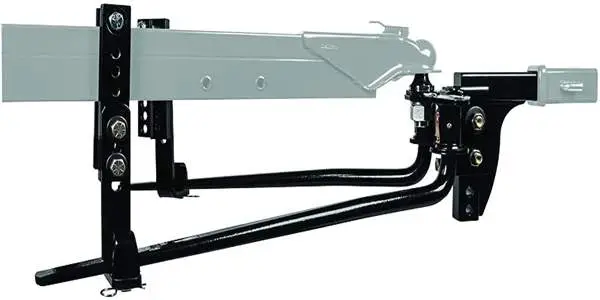

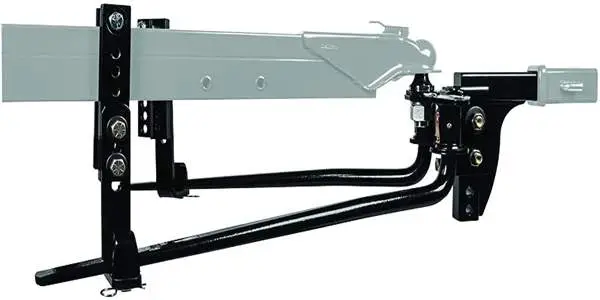

1. Husky 30849 Round Bar Weight Distribution Hitch

With a weight rating of up to 1200lbs, it comes with a sway bar ball and the hitch ball. This weight distribution hitch does an amazing job by putting the weight back on all four wheels of the tow vehicle.

This spectacular weight distributing hitch is a bolt-on setup and a perfect choice for a 26+ feet trailer. As far as its installation is concerned, it is super easy to install if you follow the directions properly.

Apart from its pros, it also has some negatives. Firstly, its powder coating is of poor quality. Secondly, you have to use a drill and self-taping screws for an anti-sway mount. Thirdly, bends ball mount on heavy load and lastly, flimsy retainer clips. See the latest price here.

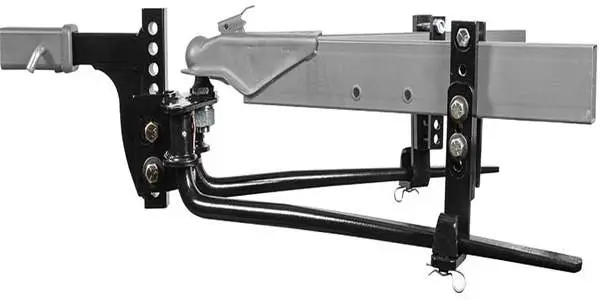

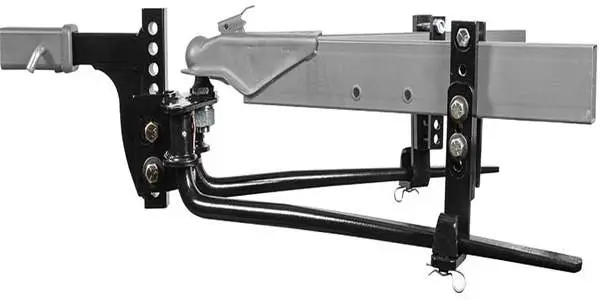

2. Husky 32218 Center Line TS with Spring Bars

Here we have another amazing WDH from Husky. Having a maximum tow load of 12,000 pounds, there will be zero sway on the highway even if the eighteen-wheelers pass by. The head unit of this hitch is fully assembled. Best of all, this hitch fits all vehicles, and also it is interchangeable. This is a comparatively heavy and sturdy anti-sway hitch.

Apart from its positives, it has some downsides, i.e., it is noisy, difficult to install, not resistant to rust, and has poor quality brackets. See the latest price here.

3. CURT 17022 Round Bar Weight Distribution Hitch

This unit from CURT is a generic one that suits any vehicle that has a 2” ball. This is a well-built hitch that comes with a sway bar and is super easy to assemble. It comes with all the things necessary to install this hitch, such as little hitch pins. On the contrary, for this sway bar ball, you will have to drill a hole. See the latest price here.

4. CURT 17062 Round Bar Weight Distribution Hitch

This round bar weight distribution hitch features a towing capacity that ranges from 8,000lbs to 10,000lbs. Constructed using solid steel, this hitch is heavy and sturdy. This hitch includes a sway bar, and also it is adjustable.

The receiver head of this hitch comes with bolt hole options allowing you to adjust the hitch’s height. CURT has designed this hitch in such a way that that it can attach to any travel trailer.

Like everything else, this hitch for a travel trailer also has some drawbacks. It does not help with sway control. The pins holding the weight bars are of extremely poor quality. Also, it rusts quickly, so you will have to be careful of it. See the latest price here.

5. Fastway e2 2-Point Sway Control Round Bar Hitch

Having a trailer weight rating of 10,000lbs and tongue weight rating of 1,000lbs, this sway control hitch offers an amazing sway control. This is the most cost-effective hitch available in the market. Compared to chain units, this hitch significantly affects the ride height and eliminates sway greatly.

Along with its pros, it has some cons, including difficult installation, poor construction, rust-prone, and misaligned welded parts. See the latest price here.

6. Equal-i-zer 4-point Sway Control Hitch

This hitch from Equal-i-zer is solid, sturdy, and heavy-duty. Apart from helping control the sway, it levels the truck so that the front-end is not higher than the truck’s rear-end.

Even if you are driving your truck at under 70kph, it will still pull well. Although this unit is comparatively expensive and not easy to install, it is still one of the best hitches in the market. See the latest price here.

7. Blue Ox BXW1000 SWAYPRO Weight Distributing Hitch

Equipped with tension bars, this equalizer type of hitch is slightly different from the other hitches in the market. It eliminates sway and equals the tongue weight of the travel trailer when hooked to the truck.

Apart from the trailer ball, it includes everything that is required for installation. It features a built-in sway control, is easy to install, and you can transfer it from one trailer to another with ease.

On the downside, it is a comparatively heavy unit and costly. This hitch does not come with a hitch ball, so you will have to purchase the ball. See the latest price here.

8. Reese Integrated Sway Control Weight Distribution Kit

Featuring a capacity of 6,000lbs, this WDH has a high-quality built. It offers metal-to-metal friction, which acts as a sway. If you want to improve the sway further, then you can add a friction sway. The product and the customer service both are amazing.

Moving on to its negatives, this WDH does not have a built-in sway, so that’s a real concern. The design of this product and the directions for its installation are extremely pathetic. Since this hitch is higher, you won’t be able to do open the rear door. The bolts mounting to the frame are hard to tighten. See the latest price here.

9. EAZ LIFT 48703 Trekker Weight Distributing Hitch

This is one of the super heavy-duty hitches available in the market. As far as its installation is concerned, installing this hitch is super-easy. What makes this hitch the best one is its ability to not produce buckling sounds while turning.

One major problem with this WDH is that it is frame compatible, so it fits only certain types. Moreover, if you sharply turn your trailer with this hitch installed, one of the bars may slip out of the holder. See the latest price here.

10. Reese Pro 49903 Round Bar Weight Distribution Kit

Last but not least, we have Reese Pro 49903 round bar weight distribution kit. It features a weight limit of 100,000 GTW and includes everything required to set it up. It also features an integrated sway control to prevent sway. This hitch does not use chains for the load springs. Instead, the spring sits in an included bracket eliminating the need for the chains.

This hitch also has some problems as well. Firstly, its sway brake is extremely poor. Secondly, anti-sway doesn’t work with surge brakes on a trailer. Lastly, sway control makes a lot of noise while making small turns. See the latest price here.

Read More About: Towing a Trailer for the First Time – An Ultimate Guide

How to Install a Weight Distribution Hitch?

Here we are at the most important part of this discussion. Many beginners question that how we can install the WDH. So here, we will explain how you can install a WDH with ease.

- Begin lining up the tow vehicle and travel trailer in a straight position and on a level pavement

- Use the trailer tongue jack and the level to raise and lower the tongue until the trailer is level

- Note the distance from the rear and front bumper of the tow vehicle to the level ground

- Deflate the air shocks with springs to their minimum recommended pressure before assembling and adjusting your weight distribution hitch

- Insert the shank into the receiver tube of your trailer hitch depending on the coupler height of your trailer

- Raise it into position so that the top of the ball is one to three inches above the previously noted coupler height

- Install the head onto the shank at the previously determined height, starting with inserting the 5-inch hex bolt and conical tooth washer through the lower hole

- Rotate the head unit tight against the shank

- The ball should be vertical or slightly tilted back

- Tighten the top bolt with a wrench just enough to hold the head firmly to the shank

- When we couple the trailer, these bolts will be torqued

- Now make sure that the lift chain is attached to the spring bars

- Apply a thick fibrous grease to the attachment points of the spring bars as it will reduce friction and extend the life of the WDH

- Insert the bottom nob of the trunnion into the lower pocket of the assembly

- Rotate it up so that the top knob passes through the entrance slot in the upper pocket handles on a wheel barrel

- As soon as it engages, lift on the back of the vehicle distributing the tongue weight of the trailer to the front of the vehicle

- Lower the coupler onto the ball just enough for the coupler to latch

- Raise the coupler around three inches with the trailer jack for easy installation of the chains under the trailer to install the chain lift brackets

- Position the spring bar so that it is parallel with the trailer frame and hold the chain vertically alongside the trailer

- Position the lift bracket so that the chain is dead center and perpendicular to the ground

- Install a bolt so that it is in contact with the frame

- Tighten it a quarter turn past that now your brackets are installed

- Raise the tongue of the trailer with the jack as it helps to make the lift bracket operation easier and safer

- Raise the chain and bar up and note which links line up with the bracket

- Insert the lift handle under the top rod above the chain attachment

- Raise the lift bracket up and over center so that it is fully seated against the mounting bracket

- Secure the bracket into position by inserting the retainer clip into the bracket

- Ensure that there is an equal amount of chain links in between the brackets and spring bars on both sides, with both brackets snapped in place

- Lower the trailer jack so that the full weight of the trailer is now resting on the hitch

- Re-measure the distances between the ground in the front and rear bumper

Since the installation process is now complete, you shall uncouple the trailer and torque all hardware to specified in the supplied instruction sheet.

Are all Vehicles Designed to use WDH?

Before we move on to the conclusion, I will be answering some common questions asked by the beginners. So the first question people ask is that can all vehicles use WDH. To put it simply, not all vehicles are compatible with WDHs. Therefore, if you are planning to get one, you must check in the owner’s manual of your vehicle whether your vehicle is compatible or not.

Moreover, if you are using a unibody vehicle, then never use a weight-distribution hitch because they won’t handle the torque and break apart under the stresses. Additionally, vehicles having a tow rating of under 5,000lbs also don’t require a WDH.

What Size Weight Distribution Hitch do I Need for a Small Travel Trailer?

It would be best if you understood this rule of thumb that a WDH size depends on the size of the travel trailer, how much load is there, what tow vehicle you are using, how much load the tow vehicle can tow, and what size WDH is required.

Now, if you are towing something small, you won’t need a weight distribution. Similarly, if your TV’s rated tongue weight is 500lbs or less and your measured tongue weight is a hundred pounds or so more, even then, you should not use a weight-distribution hitch.

Does all WDH Come with Anti-Sway or Sway Control?

The last question I would like to answer is whether all WDH come with anti-sway or sway control. Simply, not all WDHs have sway control. For instance, sway control requires friction and Equalizer has it built-in.

The majority of the WDHs available in the market nowadays are engineered with anti-sway bar so that you don’t have to purchase a separate one.

Conclusion

Towing heavy loads or travel trailers can be extremely difficult. You must outfit your towing vehicle with the best available equipment. If the weight is not equalized between the towing vehicle axels, then. As a result, the steering and braking will become unresponsive. Therefore, I would recommend you get a WDH to stay safe from these problems.