Definition and its Usage:

Floor jack is commonly known as the tool for lifting vehicles like cars in order to change a tire or the car’s undercarriage. It is used to lift vehicles from one side from the ground and with the use of floor jack we can do this easily as floor jacks use hydraulics. Floor jacks are easy and safe to use if we used them according to the specifications of manufacturers. In order to use a jack, we have to place them on the ground. Jacks are available in a variety of sizes and they lift weight according to their size.

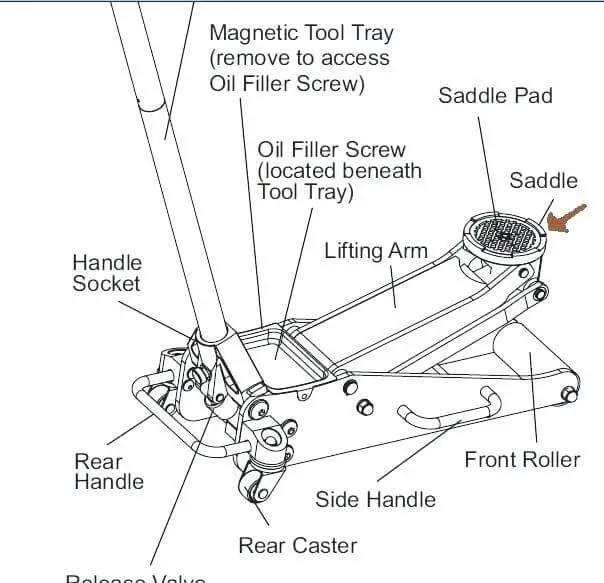

Below is the floor jack parts diagram, labeled with its parts name:

Maintenance Tips

Some of the tips I think we need to follow in order to keep the floor jack working properly:

- When you store the jack you need to make sure that the piston and the pump are pull in and you should store jack on its base not on its side in order to avoid leakage, these things enable the jack to work efficiently next time whenever we need it.

- As we put our floor jack in a garage when it is not in use so it may be possible that it covers with dust which can cause a problem so always cover the jack when not in use and you should not store the jack in the place where moisture comes in because it can damage metal parts.

- You should inspect the jack before every time you need it, like check for cracking or rust on the casing of jack and check for the leakage by looking at the ground.

- Once you have used the jack clean it by wiping out the metal parts before storing it, it keeps the jack away from dust and always check the seal to avoid leakage. If you notice some issue first fix it and then store the jack.

- You should change the jack’s oil time to time and also bleed out the air if you notice that the jack is not running smoothly because trapped air can cause damage.

- You should check the level of oil and add some oil if the rod is not moving smoothly but keep in mind that do not add oil beyond the fill line or do not overfill.

Common Problems and Their Solutions

These are some common problems I am describing below which we face in our daily usage of jack and I have also described how the floor jack troubleshooting can be done by identifying underlying reasons for problems.

Problem: Jack Won’t Lift a Weight

Problem’s definition: it means that the floor jack is not lifting the vehicle up as it was built to use for, or we can say that the jack is not holding the pressure to lift the vehicle up for changing a tire or for doing anything else.

Solution:

In order to resolve the problem i.e. the jack is not lifting a weight, the following could be the underlying issues.

Don’t overload the jack

Make sure that you are not overloading the jack which means that do not try to lift the vehicle which weighs more than the capacity the jack has. So if your jack is not lifting the vehicle up first you need to check the capacity of the jack. Some of the jacks have features for safety due to which jack stops working when it is forced to lift the vehicle more than its capacity. This can be the reason of your jack’s failure. So you need to first check the weight of a vehicle which is written on the motive force’s door pillar. Light trucks and passenger vehicles can be lifted by the jack whose weight is 2 to 3 tons.

Check the level of hydraulic oil

If your jack is not lifting weight check the level of oil because both, the low level of oil and oil beyond the fill line or overfilling of oil can cause damage and prevent the jack from lifting weight i.e. decrease its capacity of lifting weight and lower its capability.

If you have less oil than I recommend to refill the oil in the jack and use oil of some high quality rather than the ordinary oil because it can damage the parts of jack, and if the oil level is exceeded from the fill line then you should drain the extra oil from the jack. If this is the reason for your jack’s failure than after checking oil level jack will be able to hold pressure.

Remove Air From Jack

Sometimes air gets trapped in the jack which prevents the jack from lifting up the weight so if you are facing a jack failure try the process of bleeding to remove the air from the jack. In this process, you need to remove the screw of oil filler and then place the jack’s release valve in a position such that it is anti-clockwise w.r.t the handle. The next you need to do is pumping and screwing the handle as many times such that the air removed from the jack and it starts working properly.

Check The Release Valve

After the placing the jack on the ground properly, and pumped the handle but still your jack is not lifting up the weight then you need to check the tightness of the release valve such that whether it is tightened or not because if it loosens then the jack will not work. By doing this you can resolve the problem.

Do lubrication

Lubrication means to apply some oil to all the moving parts of the jack to remove friction and in order to keep them away from rust which can cause damage to the parts and it is the most important thing to do to keep the jack working. So if your jack is not lifting weight try to apply some lubricating oil.

Inspect the entire jack

After doing all the above things described above and still your jack is not able to lift the weight then it means it needs something else such that, check the casing of the floor jack may be it is ruined or cracked, check for oil leakage. Do an inspection of ram in both positions such that by pulling it in and out. These could be the reasons for your jack failure.

Problem: Floor Jack Leaks Oil

Problem Definition: means that the oil reservoir or chamber located in the floor jack starts leaking oil due to normal wear and tear.

Solution:

In order to resolve the above problem, I recommend to replace the O-rings in the floor jack, the process of replacing requires the following steps to follow:

1. Inspect the Jack:

First, you have to place the jack on the work surface and inspect the point of leakage in the oil chamber, as Jack is heavy in weight so make sure that the work surface is strong enough.

2. Release the Valve Screw:

In order to replace the O-rings, we need to loosen the valve screw which is used for raising and lowering the jack you can loosen this screw by turning it in a counterclockwise direction with the jack handle.

3. Stand Floor Jack and Drain the Fluid:

Once you have removed the valve screw stand the floor jack on it is end such that the screw is pointing towards the ceiling, then fix the jack with clamps so that it does move from its place. When the fluid leaks from the floor jack there is a chance that some wreckages remain in the fluid, set the drain pan and drain out all the fluid from the hole of valve screw and then put the jack back up to its position.

4. Place New O-Ring:

In order to stop leakage, you need to replace the O-ring which is the reason of leakage when it becomes faulty, the O-ring is on the valve screw you can remove it easily with the screwdriver after removing clean the screw with the rag and then fix a new O-ring.

5. Refill Jack:

Now after replacing fill the jack with the premium fluid recommended by your manufacturer, put the funnel on the hole of screw valve and pour fluid until it reaches the fill line, do not overfill the fluid.

6. Place the Valve Screw:

After replacing the O-ring and filling up the jack with the fluid place the valve screw again and tightens it in a counter clockwise direction and then check the jack for the leakage by raising and lowering the weight using the valve screw.

Problem: Overload Valve Was Accidentally Turned

Problem Definition: Overload valve is a safety feature for the floor jack which has the warning “don’t open” so if it is turned on in wrong direction it causes damage.

Solution:

The overload valve feature prevents the jack from working if it forced to lift the weight more than its capacity. If the overload valve is turned by you accidentally then I recommend seeking help from the hydraulic jack experts because turning it on in the wrong direction changes the tension of spring and as a result there will be a change in the functionality of jack.

Problem: Wheels did Not Roll Properly

Solution:

If the wheels of the floor jack is not rolling properly then I recommend you to use some lubricating oil on the wheels to reduce friction. This condition occurs when you store the jack after usage without wiping out the dust and when you store it in a place where moisture comes in due to which the wheels becomes rusted and does not roll properly. Make sure that the oil you are using for the lubrication should be a premium one, avoid using the ordinary oil because it can damage the metal of the wheels.

Problem: Cracking, Bending or Breaking of a Floor Jack

Solution:

If you notice that the case or frame of the jack is cracked, bent or broken then you should stop using the jack because it is not safe to use it and you should replace it with a new one. The jack’s stability depends on the frame of the jack, if you notice that the frame of jack is bending than it means it is not holding the vehicles pressure, and it would be a risk to use jack after facing this condition. If there is only a scratch on the frame then it is not a serious problem, but a jack with bent frame must be replaced with a new one, do not try to fix it.

Problem: Milky or Foamy Oil Leakage

Solution:

This problem occurs when the water or air mix up with the oil, this happens when we do not wipe the dust with a rag from the drain plug. So, to resolve this problem we need to change the oil or refill in the oil reservoir. To refill the oil, follow the process:

- First, locate the drain plug on your jack, it may be under the tool tray or on the housing depends on your model of jack.

- Clean the drain plug from the rag to wipe out the dirt or grease.

- Then open the plug of the drain with a wrench.

- Place the drain pan and position the jack such that all the oil drains out of the drain plug hole.

- Put the funnel on the drain plug hole and pour hydraulic oil into the oil reservoir make sure the oil is premium recommended by your manufacturer and pour the oil in such a way that dirt particles or other materials do not fall into the oil reservoir.

- Remove the release valve and pump the handle several times in order to bleed out the air from the jack then put the release valve into its position.

Close the drain plug and wipe off any extra oil dripped during the process.